Air sparging is an increasingly popular remediation technique due to its ability to remove contaminants from groundwater.

The remediation team will inject air into a contaminated area during air sparging. The injection causes semivolatile and volatile contaminants to experience a transfer of mass.

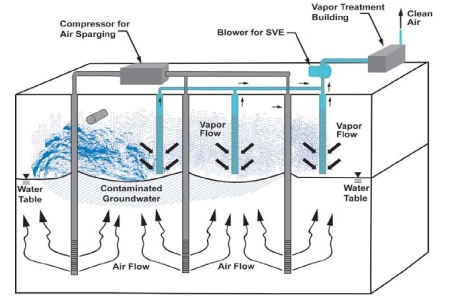

In other words, the air bubbles move the contaminants upward, where they can be captured using a venting system. By adding oxygen to the groundwater, air sparging also accelerates the degradation of contaminants.

Air sparging offers several advantages when compared to traditional groundwater remediation techniques.

For one thing, the approach is less expensive than installing an above-ground remediation system. Air sparging is also conducted with readily available devices, meaning the system can be set up and implemented while minimizing disruptions to site operations.

Table of Contents

What Is Air Sparging Used To Do?

VOCs are frequently found in underground storage tanks that hold petroleum products. Air sparging causes the VOCs to undergo volatilization from the groundwater, meaning the contaminants are transferred into air bubbles and captured by the remediation system.

Air sparging is most effective when used to remove lighter gasoline-related VOCs, including toluene, xylene, and benzene. Unfortunately, this technique isn’t as effective at eliminating kerosene or diesel fuel. Still, it can be used for oil contamination events, as it will remove or reduce the concentration of at least some of the present VOCs.

Moreover, air sparging can be used in conjunction with other remediation techniques. However, it’s most effective when paired with soil vapor extraction.

Is Air Sparging Effective?

Air sparging is effective so long as the area over the contaminated site is permeable. However, ground permeability must be assessed and verified before attempting the technique.

If a site isn’t permeable, air sparging could spread contamination instead of remediating it, as the air bubbles wouldn’t be fed back into the air sparger system but would be dispersed throughout the site.

Alpha-Omega Training and Compliance, Inc. has experience evaluating various contaminated sites to determine whether air sparging is a viable remediation solution. Our team can also assess for other air sparging-related issues, such as whether the technique will yield uniform permeation across an entire site.

The contamination must go at least three feet deep for air sparging to be effective. Otherwise, the process could spread contaminants or yield non-uniform results.

What Is a Sparging System?

When installing an air sparging system, our team must first drill an injection well into the contaminated water table. Next, our team will put the manifold and tank into position. Once all the necessary components have been installed, we’ll begin pumping air into the well, initiating the volatilization process.

Typically, the air is enriched with supplemental oxygen. Various nutrients may also be added to accelerate the biodegradation process. Adding a nutrient tank to the system will increase costs, but it can also improve the efficacy of the remediation efforts.

What Is the Difference Between Air Sparging and Soil Vapor Extraction?

Air sparging is intended to extract contaminants from the groundwater using volatilization. Conversely, soil vapor extraction focuses on removing contaminated vapors from the soil. Since each technique addresses different media (water versus ground), they’re typically used in conjunction.

During air sparging, contaminants are released from groundwater and captured by the remediation system. However, some pollutants won’t fully permeate the soil but will instead become trapped. Using soil vapor extraction after air sparging lets our team absorb any newly released contaminants.

Soil vapor extraction creates a negative pressure zone around the target area. The negative pressure controls the flow of contaminated air and helps prevent the VOCs from spreading to other site areas.

Is Air Sparging in Situ?

In situ solutions like air sparging yield many benefits compared to other, less efficient remediation solutions like groundwater pump-and-treat systems.

Most notably, in situ air stripping can produce faster results than traditional remediation methods, minimizing project delays and streamlining permitting and construction processes.

Additionally, air sparging and other in situ solutions are more cost-effective in the long term. Finally, these solutions can be applied to various contaminants, including pesticides, petroleum products, wood preservatives, chlorinated solvents, and many others.

Most in situ technologies destroy VOCs on-site, meaning you won’t incur secondary cleanup or disposal costs during remediation. However, such solutions also generate heat as a byproduct of remediation, increasing microbial activity and accelerating the natural decomposition of VOCs.

Air Sparging and Soil Vapor Extraction Remediation Methods

Air Sparging (AS) and Soil Vapor Extraction (SVE) are active, in-situ remediation methods implemented to remove Volatile Organic Compounds (VOCs) from sub-surface soils and shallow groundwater for treatment above ground. AS systems are designed to aerate contaminated soil, groundwater, and volatile VOCs into a gaseous state by injecting air into the vadose zone1. SVE systems extract the volatilized VOCs by inducing vacuum pressure in recovery wells and removing the vapors. These two systems are often operated in combination with each other and can be used with other remediation methods individually or simultaneously.

Using air to convert mobile-phase aqueous contaminants to vapor for extraction by vacuum is most effective for VOCs because of their unstable physical state and proclivity for volatilization. VOCs are typically associated with petroleum products and chlorinated solvents, so AS/SVE systems are often implemented to remediate gas stations and dry-cleaning facilities. These methods are especially useful on sites where contamination exists under buildings, parking lots, and roadways. The above-ground components of treatment systems using AS/SVE are typically discreet and hidden in plain sight, positioned around gas stations and shopping plazas with dry cleaners. According to U.S. Environmental Protection Agency (USEPA) statistics, AS/SVE systems are used at approximately 285 Superfund sites. (United States Environmental Protection Agency, 2012)

Choosing an Air Sparging Service

Air sparging remediation is a highly effective technique for treating contaminated groundwater. On its own, an air sparger can remove a significant amount of contaminants from polluted groundwater. However, air sparging is most effective in conjunction with soil vapor extraction.

That said, correctly applying air sparging equipment requires extensive knowledge and expertise.

If performed incorrectly, air sparging could exacerbate the issue rather than remediating groundwater contamination. You should always partner with an experienced air sparging provider like Alpha-Omega Training and Compliance, Inc. (AOTC).

At AOTC, we have the experience, equipment, and skills to determine whether air sparging remediation is a good fit for your project and, if so, take the necessary steps to clear up the contamination.

Along with our site assessment, we can perform numerous other types of site cleanup as part of our environmental remediation services. Contact our team today to learn more about our process and schedule a consultation.