What is industrial hygiene? This article answers that question and a few other key related ones:

- What are industrial hygiene and occupational health & safety?

- Why is industrial hygiene important?

- What is an industrial hygiene assessment?

- What are the types of hazards defined by industrial hygiene?

Table of Contents

What Is Industrial Hygiene?

When someone asks, “What is industrial hygiene?” or “What are the types of hazards defined by industrial hygiene,” they are inquiring about a topic intertwined with occupational health and safety. According to the American Board of Industrial Hygiene (ABIH), occupational health is virtually synonymous with industrial hygiene. These are the terms occupational hygiene and environment, health and safety (EHS).

Industrial hygiene is the science of safeguarding and bolstering people’s safety and health in their communities and workplaces, per the ABIH. Physical, biological, chemical, and ergonomic factors in people’s workplaces, homes, or other settings can all be risks to safety and health. Industrial hygienists focus on the anticipation, identification, assessment, and control of these hazards – preserving wellness.

When the American Public Health Association approved the creation of an Industrial Hygiene Section in the early twentieth century, this field started to get recognition. Dr. Alice Hamilton’s work in connecting toxic exposure to workers’ illnesses was central to promoting the need for industrial hygiene as well.

Early adopters of industrial hygiene programs tended to center their efforts on reducing noise and chemical hazards. At the time, very few people had the requisite expertise and were offering themselves as industrial hygienists. Instead, organizations used their engineers, physicians, toxicologists, chemists, and other scientists in their ranks to assess and optimize workplace health and safety. Industrial hygiene has become a much more widespread and studied concept between then and now.

Industrial hygiene is about maintaining cleanliness while removing toxicity from work environments using control methods to mitigate health impacts from hazards. In contrast, occupational health studies hazards in terms of their health impacts; striving to prevent workplace illnesses, occupational health focuses on the consequences of hazard exposure. Regardless of this technical distinction, the terms are often used interchangeably.

Why is industrial hygiene important?

Industrial hygiene is important because it applies science to workplace health and safety problem-solving while unifying all personnel and management through a shared goal. By helping you reduce risks within your workplace, this field helps you avoid the negative impacts of injuries and illnesses, including losses of time and money. Your end result is a more productive climate with higher morale.

The Occupational Safety and Health Administration (OSHA) notes that the field of industrial hygiene is important to the assessment of worksites for health hazards. Industrial hygienists are central to OSHA’s work because the goal of occupational health is to protect the wellness of the workforce through hazard control; in fact, more than 2 in 5 OSHA compliance inspectors are industrial hygienists. As new physical, biological, chemical, or ergonomic hazards become apparent over time, industrial hygienists continuously develop standards to address them.

What is an industrial hygiene assessment?

An industrial hygiene assessment is just that, an information-gathering process checking how well your space meets industrial hygiene standards. It gives you an idea of where there might be issues to address. Through this assessment, also called a worksite analysis, the inspector or consultant evaluates, analyzes, and studies how worksite risks impact health. The process involves the detection and measurement of types of hazards defined by industrial hygiene throughout all of an organization’s operations and roles. After the assessment, the industrial hygienist provides the company with suggested steps to correct any hazards.

What are the types of hazards defined by industrial hygiene?

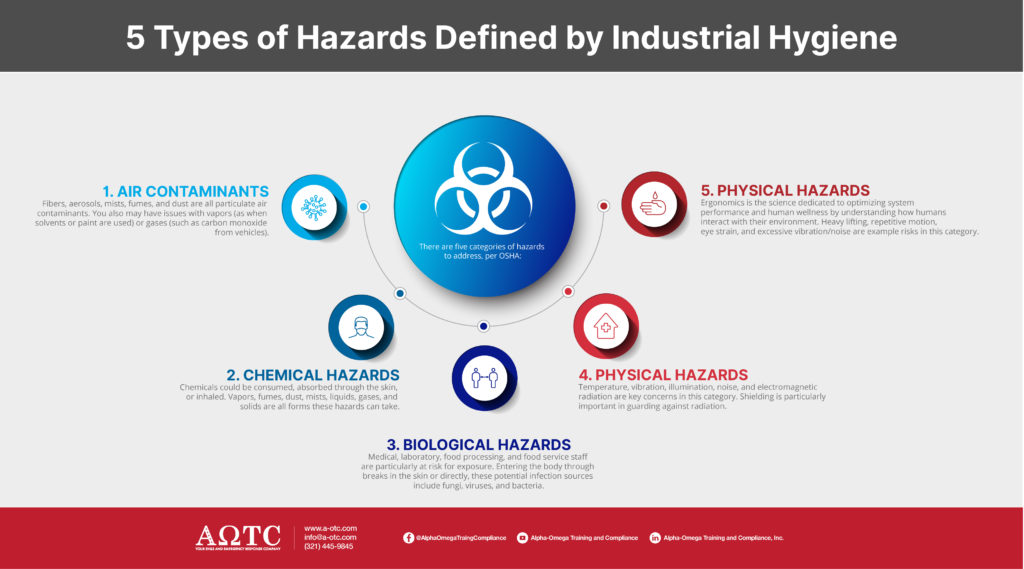

There are five categories of hazards to address, per OSHA:

#1. Air contaminants — Fibers, aerosols, mists, fumes, and dust are all particulate air contaminants. You also may have issues with vapors (as when solvents or paint are used) or gases (such as carbon monoxide from vehicles).

#2. Chemical hazards — Chemicals could be consumed, absorbed through the skin, or inhaled. Vapors, fumes, dust, mists, liquids, gases, and solids are all forms these hazards can take.

#3. Biological hazards — Medical, laboratory, food processing, and food service staff are particularly at risk for exposure. Entering the body through breaks in the skin or directly, these potential infection sources include fungi, viruses, and bacteria.

#4. Physical hazards — Temperature, vibration, illumination, noise, and electromagnetic radiation are key concerns in this category. Shielding is particularly important in guarding against radiation.

#5. Ergonomic hazards — Ergonomics is the science dedicated to optimizing system performance and human wellness by understanding how humans interact with their environment. Heavy lifting, repetitive motion, eye strain, and excessive vibration/noise are examples of risks in this category.

Your Industrial Hygiene Company

Do you need to ensure your workers are protected through an industrial hygiene assessment? At AOTC, our first step is to evaluate your business needs and develop a customized program. Contact us today to discuss your options and schedule your courses today.